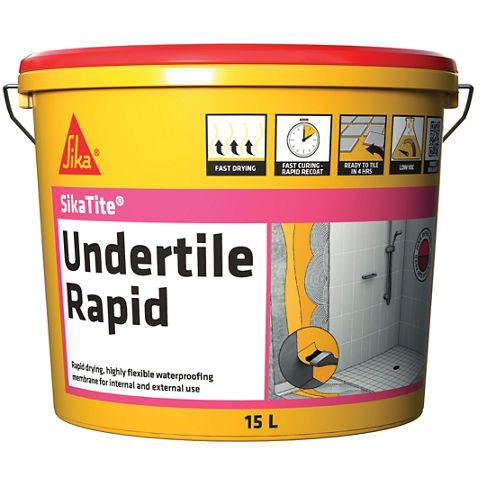

SikaTite® Undertile Rapid

A HIGHLY FLEXIBLE CLASS III, RAPID DRYING, UNDER TILE WATERPROOFING MEMBRANE

SikaTite® Undertile Rapid is a highly flexible, Class III, rapid drying, waterproofing membrane suitable for internal and external use. SikaTite® Undertile Rapid is designed to bond to a wide variety of substrates and is micro fibre reinforced for improved tensile strength and crack bridging.

- Rapid drying, overcoat in 2 hours

- Flood test after 24 hours

- High extensibility >300%

- Blue colour

- Internal & external applications

- Water based - easy to use

- Low VOC

- Residential and commercial applications

- Compatible with Sika and Davco range of tile adhesives

- Premixed ready to use

- Class III, highly flexible